We understand the particularity of steel and will use professional equipment and methods to ensure the accuracy and representativeness of the samples. In the production process, we take samples, whether it is sheet metal, pipes, or other forms of steel, we can meet your needs.

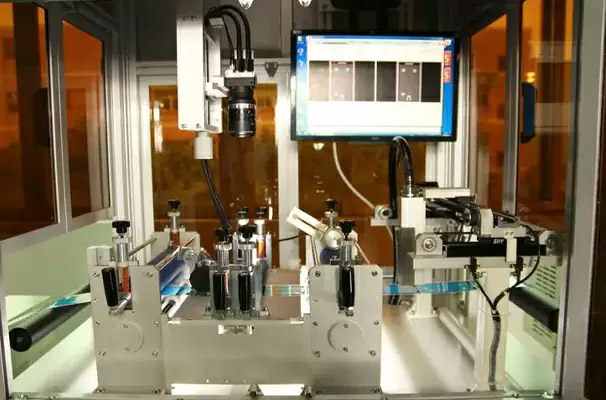

Using advanced measuring equipment and technology, we will accurately measure the dimensions of steel, including length, width, thickness, and other parameters, to ensure compliance with your specifications.

We are equipped with advanced chemical analysis equipment that can accurately detect the chemical composition of steel, including carbon content, alloy element content, etc., to ensure compliance with your quality standards.

Through precise testing and analysis, we ensure that the production yield of steel reaches the expected level, improving production efficiency and product quality.

We will conduct tensile tests on steel samples to evaluate their strength and toughness, ensuring they meet your strength requirements.

Using professional equipment and methods, we conduct bending tests on steel to evaluate its deformation and performance under stress conditions.

We will conduct hardness tests on steel samples to evaluate their wear resistance and compressive performance, ensuring they meet your requirements.

Using precision weighing equipment, we will conduct accurate weight testing on the steel to ensure compliance with the specified weight requirements.